Have we ever wished our off-grid power setup felt more reliable, compact, and efficient—without us constantly worrying about voltage fluctuations or complex wiring?

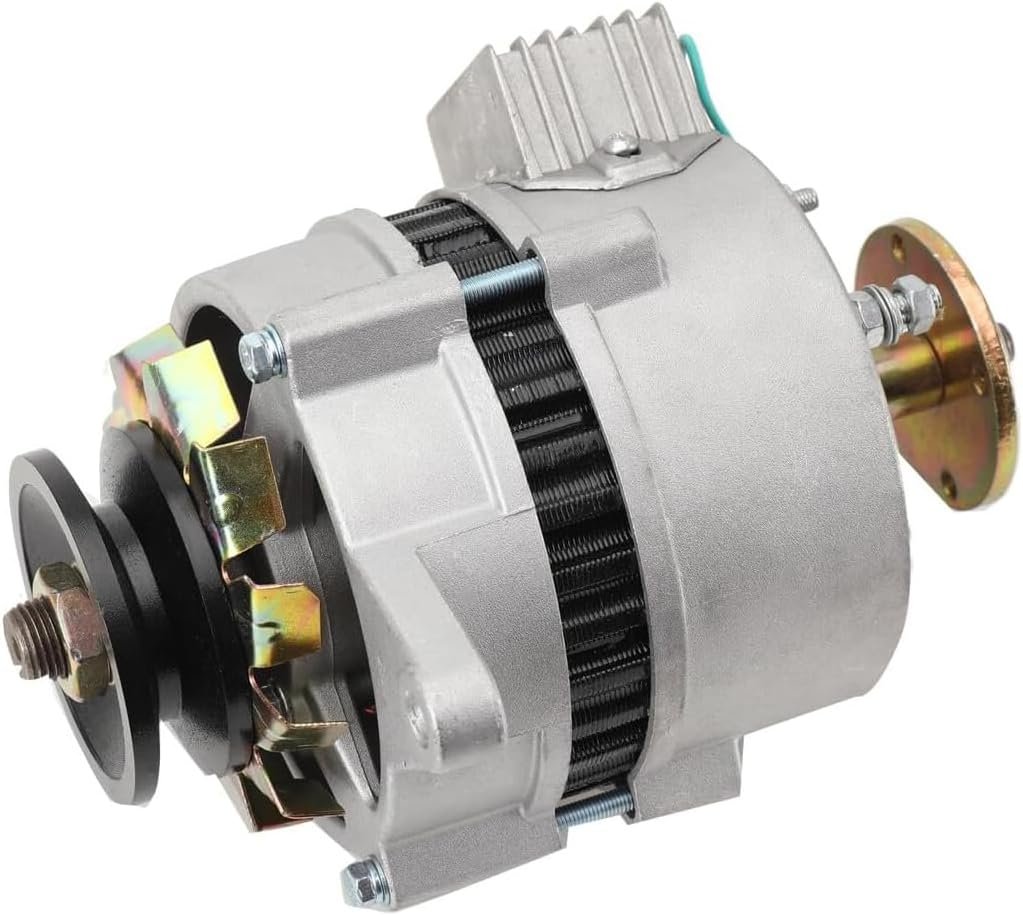

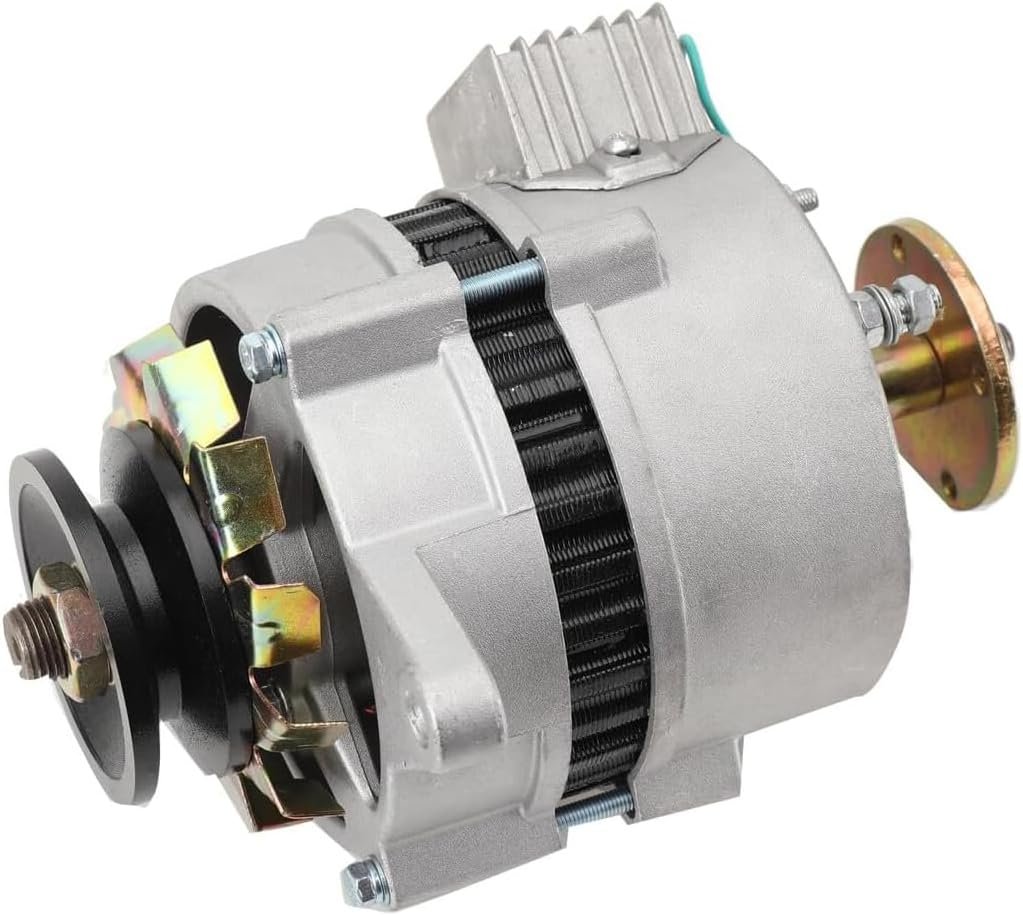

What Is the Permanent Magnet Alternator Generator 1500W AC 14V PMA?

This Permanent Magnet Alternator Generator 1500W AC 14V PMA Low Rpm Single Phase AC/DC Synchronous Generator with Built-in Voltage Stabilizer is designed as a compact, efficient power source for charging batteries and running low-voltage systems. We get a permanent magnet alternator with its own rectifier and full‑wave voltage stabilizer built right in, which means fewer external components to buy and wire.

Instead of a simple alternator that needs an external regulator and rectifier, this unit combines those functions into one housing. That saves us space, simplifies installation, and can reduce points of failure in our system.

Key Specifications at a Glance

Before we talk about performance and real-world use, we find it helpful to see the main specs laid out clearly. That way we know whether it fits our particular project or not.

| Feature | Specification |

|---|---|

| Product Name | Permanent Magnet Alternator Generator 1500W AC 14V PMA |

| Type | Permanent magnet, single-phase AC/DC synchronous generator |

| Power Rating | 1500W |

| Voltage Output | 14V |

| Output Type | AC single-phase (with built-in rectifier & stabilizer for DC use) |

| Rotor Type | Magnetic strip rotor |

| Rectifier/Regulator | Built-in silicon rectifier and full-wave voltage stabilizer |

| Shell Material | Aluminum |

| Internal Winding Material | Pure copper |

| Use Case | Dual-purpose: charging and lighting |

| Inner Machine Foot Size | 7.1 cm |

| Outer Machine Leg Size | 10.8 cm |

| Packing Size | 26 × 18 × 15 cm |

| Net Weight | 3.5 kg |

| Gross Weight | 3.95 kg |

These specs tell us this generator is built for 14V systems, making it naturally suited to 12V battery banks, automotive-style applications, and small off-grid setups. The 1500W rating is significant for such a compact machine, especially at low RPM operation.

Design and Build Quality

Construction Materials: Aluminum Shell and Pure Copper Windings

The generator housing uses aluminum for the shell and pure copper for the internal windings. We really appreciate that combination because aluminum keeps the unit lighter and more resistant to corrosion, while pure copper windings mean better conductivity and typically better efficiency.

Using pure copper also tends to improve overall durability under sustained current loads. In other words, the generator should handle continuous operation more gracefully than units that cut corners with cheaper materials.

Compact and Practical Form Factor

With a packing size of 26 × 18 × 15 cm and a net weight of 3.5 kg, this is a relatively compact and portable generator head. We can see it fitting easily into tight spaces on a small turbine frame, a DIY generator mount, or inside a compact power box.

The mounting foot sizes (7.1 cm inner, 10.8 cm outer) give us enough information to start planning a mounting plate or bracket. We would likely design a small steel or aluminum bracket with slotted holes to fine-tune alignment with whatever prime mover we are using (engine, turbine, or other mechanical source).

Internal Layout: Built-In Rectifier and Voltage Stabilizer

One of the best aspects of the design is the integration of the rectifier and full-wave voltage stabilizer inside the generator itself. We no longer need a separate rectifier block or external regulator for basic 14V DC use.

This internal layout means:

- Fewer external connections and boxes

- Less wiring complexity

- A cleaner installation, especially in cramped environments

For us, that is a big plus if we want quicker, more straightforward assembly with fewer components that can loosen or fail.

Technology: Permanent Magnet + Silicon Rectifier System

How the Permanent Magnet System Works

This generator uses a permanent magnet rotor, described as a “magnetic strip rotor.” Instead of an electromagnet rotor that needs an external excitation current, the rotor’s magnetic field comes from permanent magnets.

That gives us several advantages:

- No separate field winding or excitation circuit

- Typically better efficiency at low RPM

- Simpler construction with fewer parts to break

- Immediate generation of power once the rotor turns

For low-RPM applications, such as wind turbines or slow-running engines, this can be a big advantage. We do not need to hit very high RPMs before the generator starts producing useful power.

Combined Excitation Silicon Rectifier and Constant Voltage Behavior

The product description calls this a “Permanent Magnet Silicon Rectifier Generator” that combines features of an excitation silicon rectifier generator and a permanent magnet constant voltage alternator. In practical terms, that means:

- It behaves like a permanent magnet alternator (simple, robust, low-RPM capable).

- It also includes circuitry that stabilizes voltage via a full-wave rectifier and regulator.

The built-in voltage stabilizer helps us maintain a more consistent output around 14V for battery charging, even when the input RPM changes within a certain range. That is especially valuable in real-world setups where rotor speed fluctuates.

Power Output and Performance

Understanding the 1500W, 14V Rating

The generator is rated at 1500W with a 14V output. To interpret that:

- 1500W at 14V corresponds to roughly 107A of current (1500 ÷ 14 ≈ 107).

- That is a substantial current capability, suggesting we can charge a 12V battery bank relatively quickly if our mechanical drive (engine or turbine) can supply enough torque and RPM.

In a real setup, we would typically design for less than absolute peak power for continuous duty—perhaps around 60–80% of rated capacity—to avoid heat buildup and extend lifespan. So we might plan for around 900–1200W continuous output under ideal cooling and airflow.

Low RPM Operation

The description emphasizes “Low Rpm,” which is often essential for off-grid and renewable setups. While precise RPM ranges are not listed, permanent magnet alternators like this are usually designed to provide usable output at much lower speeds compared to conventional automotive alternators.

This trait is particularly beneficial for:

- Small wind turbines where rotor speeds are inherently limited

- Slow diesel or gasoline engines used for efficient fuel consumption

- Water wheels or other mechanical sources with modest rotational speeds

We still need to match RPM using pulleys, belts, or gearing, but the threshold for effective generation is usually lower than conventional designs.

Efficiency and Power Stability

With its permanent magnet design and built-in full-wave voltage stabilizer, we can expect:

- Decent conversion efficiency from mechanical power to electrical power

- Less fluctuation in voltage when RPM or load shifts within normal ranges

- Improved reliability due to fewer external electronic modules

We still need to manage heat and ensure good airflow, especially near peak loads, but the integrated design supports a more stable, reliable power output profile.

Voltage Regulation and Electrical Behavior

Built-In Full-Wave Voltage Stabilizer

The full-wave voltage stabilizer is central to how this generator behaves in a DC charging setup. It transforms the internal AC output into a more stable DC-like output suitable for battery charging and lighting.

What this means for us:

- Better protection for sensitive 12V lighting or electronics (through a battery buffer)

- Reduced risk of over-voltage (within the design limits) when rotational speed increases suddenly

- Less need for extra regulators in simple 12V battery charging systems

We still might pair it with additional protection (like a fuse, circuit breaker, or separate charge controller) for complex or valuable systems, but for basic setups the built-in stabilizer is a big advantage.

AC and DC Usage: Dual-Purpose Output

Even though the product is described as “AC single-phase,” the built-in rectifier and stabilizer make it effectively dual-purpose:

- Internally it generates AC.

- Through its own rectification and regulation, it provides a stable voltage suitable for DC battery charging and lighting.

The listing emphasizes “dual-purpose charging and lighting,” which aligns well with typical 12V systems. We can hook this up to a 12V battery bank and then run DC lights, inverters, or other 12V accessories off that bank.

Wiring and Installation

Basic Wiring for Charging and Lighting

The product details give us a concise wiring method. For charging and lighting with a battery:

- Connect the positive terminal of the battery to the generator’s + terminal through a live wire controlled by a switch or button.

- Connect the negative terminal of the battery to ground (chassis or a dedicated negative bus).

In practice, we would likely:

- Run a heavy-gauge positive cable from the battery positive to a fuse or circuit breaker.

- From the fuse/breaker, connect to a switch or relay that we can control.

- From the switch/relay, run the cable to the generator’s positive terminal.

- Bond the battery negative to the generator housing ground if appropriate, or run a dedicated negative cable.

We always want to size the wiring appropriately for the expected current. Since 1500W at 14V involves high current, we would use thick cables and proper connectors to avoid overheating and voltage drop.

Mounting and Mechanical Integration

For physical installation, we focus on:

- The inner machine foot size: 7.1 cm

- The outer machine leg size: 10.8 cm

We would build or adapt a mounting plate with properly spaced holes or slotted openings to accommodate those dimensions. Alignment is essential to prevent vibration, especially if we are connecting with belts or couplings.

Good mechanical integration also includes:

- A firm, rigid mounting surface to prevent misalignment

- Rubber isolators if we want to reduce vibration transfer

- Correct tension on belts or couplings to prevent slippage

Use Cases: Where This Generator Fits Best

Off-Grid and Backup Power Systems

For those of us with small off-grid cabins, workshops, or remote setups, a 14V, 1500W permanent magnet alternator can serve as a robust charging source. When paired with a battery bank and inverter, we can support:

- LED lighting and small electronics

- DC pumps and fans

- Occasional higher-wattage loads through an inverter

This generator head would typically be driven by a small gasoline or diesel engine, or as part of a hybrid renewable system with wind or water power.

Renewable Energy Projects (Wind, Micro-Hydro, DIY Systems)

The low RPM capability and permanent magnet design make this generator appealing for renewable energy projects:

- Small wind turbines on towers or rooftops

- Micro-hydro systems using streams or canals

- Experimental human-powered or pedal-generator setups

Because it has a built-in rectifier and stabilizer, our wiring can be simpler. We can route the generator output straight to batteries (with a proper disconnect and protective devices) instead of dealing with separate rectifier blocks and regulators.

Automotive, Marine, and Mobile Applications

Although this unit is not a standard automotive alternator, its 14V output and robust current capacity mean it could be used in custom automotive, marine, or RV projects, especially those with:

- Custom-built auxiliary charging setups

- Dedicated battery banks for inverters and accessories

- Mobile workstations or service vehicles

We just need to ensure proper mounting and safe mechanical coupling to the engine.

Advantages of This Generator

Integration: Rectifier and Stabilizer Included

We really like that the generator combines:

- A permanent magnet alternator

- A silicon rectifier

- A full-wave voltage stabilizer

That integration offers us:

- Simpler system design and fewer separate boxes to mount

- Reduced wiring complexity and potential points of failure

- Quicker installation and easier troubleshooting

For many projects, that feature alone can justify choosing this model over a bare alternator head.

High Output for a 14V System

With a rating of up to 1500W at 14V, we get:

- Enough power to support fast charging of 12V battery banks

- Ability to run multiple DC loads through a battery simultaneously

- Capability to support small to moderately sized off-grid setups

We just have to make sure that our mechanical drive (engine, turbine, etc.) can realistically supply enough torque and speed to unlock that capacity.

Permanent Magnet Reliability and Low-RPM Capability

Because it uses a permanent magnet rotor:

- We have fewer electrical parts to fail compared to wound-field alternators.

- We generally get better performance at lower RPM.

- There is no need for an external excitation circuit.

For renewable energy setups and slower mechanical drives, that is a big advantage, providing us with power where conventional alternators might struggle.

Sturdy Construction and Materials

Using an aluminum shell and pure copper windings:

- Offers a solid balance between weight and strength

- Helps with heat dissipation

- Promotes long-term reliability under continuous operation

Those are exactly the materials we would expect in a generator designed for regular use.

Limitations and Considerations

14V-Only System Design

The generator is designed for a 14V output, optimized for 12V systems. That is ideal for:

- Automotive-style batteries

- 12V lighting and accessories

- Inverters meant for 12V input

However, if we want higher-voltage systems (24V, 48V, etc.), we would either need:

- Different hardware, or

- More complex power electronics to step up voltage, which adds cost and complexity

So this generator is most suitable when we intentionally commit to a 12V-based architecture.

High Current Requires Careful Wiring

To deliver 1500W at 14V, we are dealing with high current levels. That means we must pay attention to:

- Cable sizing

- Connection quality

- Fusing and overcurrent protection

- Heat management in our wiring paths

If we undersize cables or skip proper protection, we risk voltage drop, damage, or safety issues. This is not unique to this generator, but the power rating makes it an important consideration.

Limited Detailed Documentation in the Listing

From the product details, we can see the core specs, but some things are not fully spelled out, such as:

- Exact RPM vs. output curves

- Detailed wiring diagrams

- Recommended continuous current limits

- Environmental protection rating (IP rating, weatherproofing, etc.)

We would likely want to request or find a user manual or technical datasheet from the seller or manufacturer. That would give us more precise guidance for optimal use and long-term reliability.

Real-World Use: What We Can Expect

Day-to-Day Operation in a Small System

In a basic setup, we might use:

- This generator mounted to a small gasoline engine

- A 12V deep-cycle battery bank

- A 12V DC fuse box for lights and small devices

- An inverter for occasional AC loads

In that context, we can:

- Start the engine when battery voltage drops

- Let the generator charge the bank until voltages are back in a safe range

- Use the battery power at night or when the engine is off

The built-in voltage stabilizer will keep charge voltage more controlled, helping to avoid over-voltage scenarios under normal operation.

Integration with Wind or Micro-Hydro

For renewable projects, we might:

- Connect this generator to a small horizontal-axis wind turbine

- Or to a micro-hydro wheel or turbine in a stream

We would design gearing or pulley ratios so that our typical wind or water speeds result in the generator spinning at an RPM that yields usable power and good charging behavior. With the permanent magnet and built-in stabilizer, we should see somewhat smoother performance even with fluctuating input speeds.

We may still want a dedicated charge controller for sophisticated battery management, but the generator does a lot of the heavy lifting by itself.

Installation Tips and Best Practices

Electrical Safety and Protection

We would strongly consider:

- Installing a fuse or DC breaker close to the battery positive terminal

- Using adequately sized cables based on expected current

- Ensuring all connections are tight, corrosion-free, and well insulated

- Considering an external charge controller for expensive or sensitive battery banks

A well-protected system is easier to maintain and far less likely to cause damage if something goes wrong.

Cooling and Ventilation

Although the aluminum shell helps with heat dissipation, we should:

- Provide adequate airflow around the generator

- Avoid enclosing it in a tight, unventilated box

- Check for heat buildup during extended high-load operation

If we plan to run it near maximum load for long periods, we may want additional cooling measures, such as forced air ventilation in the housing or compartment.

Mechanical Alignment and Vibration Control

To keep the generator healthy and our system quiet:

- Ensure proper shaft alignment (if using a direct-drive coupling)

- Maintain correct belt tension if using a belt drive

- Use sturdy mounts to reduce vibration and prevent loosening

Regular inspection for loosened bolts, misalignment, or unusual noise can help us catch issues early.

Pros and Cons Summary

To help us quickly decide whether this product fits our needs, we can summarize the main strengths and trade-offs.

Pros

-

Integrated rectifier and full-wave voltage stabilizer

Reduces external components, simplifies wiring, and stabilizes output. -

Permanent magnet design

No excitation circuit needed, good low-RPM performance, and higher reliability. -

1500W at 14V

High current capability for 12V battery banks, enabling substantial off-grid power capacity. -

Dual-purpose charging and lighting

Naturally suited for 12V battery charging and DC lighting systems. -

Quality materials

Aluminum shell and pure copper windings for durability and efficient operation. -

Compact and reasonably lightweight

Easy to integrate into small mechanical and electrical designs.

Cons

-

Limited to 14V systems

Best suited only for 12V-style setups; less ideal if we want higher-voltage systems. -

High current demands careful wiring

Requires proper cable sizing and protection to handle up to 1500W safely. -

Incomplete public documentation

We may need to seek additional RPM/output data and detailed wiring diagrams from the supplier.

Who Is This Generator Best For?

We see this generator as a strong fit for:

- Those of us building or upgrading small off-grid power systems based on 12V batteries.

- DIY enthusiasts wanting a compact, integrated generator head for custom projects.

- Hobbyists and builders working on wind, micro-hydro, or engine-driven chargers.

- Users who value simplicity and robustness over complex external electronics.

If our system already runs on 12V, and we are comfortable designing for high current with proper protection, this product offers a lot of capability in a relatively small package.

On the other hand, if we are focused on 24V or 48V architectures, or if we want a plug-and-play consumer generator with built-in AC sockets and everything pre-wired, we might be better served by a different solution.

Final Thoughts

Taking all of this into account, the Permanent Magnet Alternator Generator 1500W AC 14V PMA Low Rpm Single Phase AC/DC Synchronous Generator with Built-in Voltage Stabilizer stands out as a capable, integrated power source tailored to 12V systems.

We get:

- A robust permanent magnet alternator

- A built-in silicon rectifier

- A full-wave voltage stabilizer

- 1500W of potential power at 14V

- Compact, aluminum-bodied construction with pure copper windings

For us, that combination makes it an appealing choice if we are building a serious 12V-based charging system, whether for backup power, off-grid living, or renewable energy projects. As long as we design our wiring, protection, and mechanical mounting carefully, this generator can become a central, reliable component in our custom power setup.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.