Have we ever pulled the starter cord on our generator, only to feel that awful snap and realize the recoil is done for right when we need power the most?

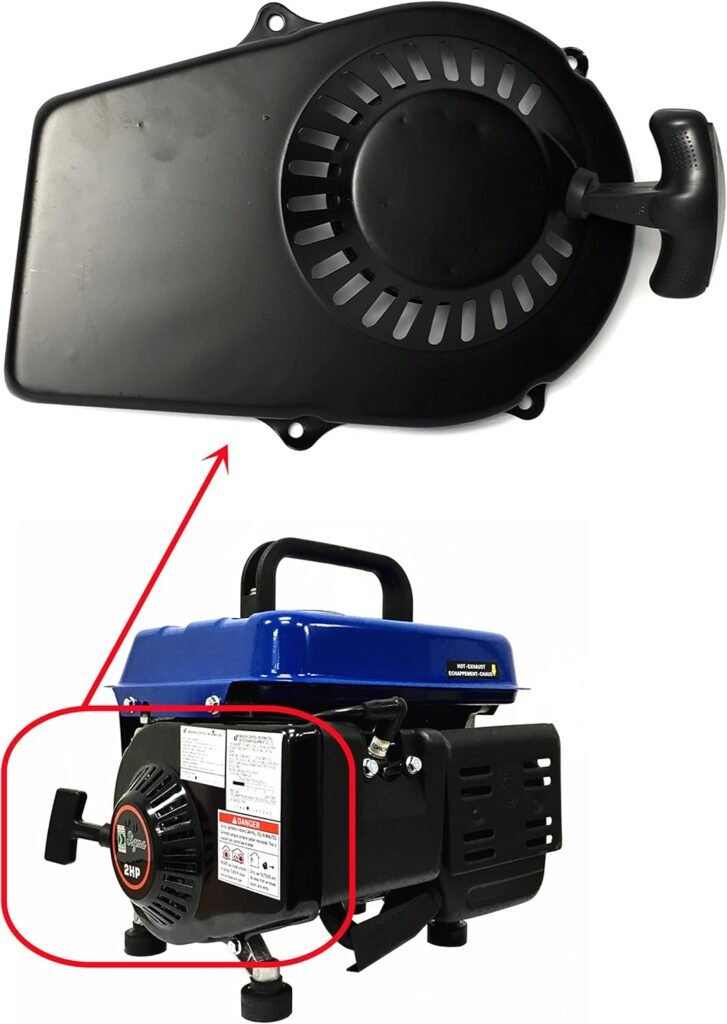

Understanding What This Recoil Pull Starter Actually Is

When we talk about a recoil pull starter, we are really talking about the heart of how our small gas generator comes to life. This part is the mechanism that engages the engine when we pull the cord, lets it spin up, and then retracts the rope smoothly.

For the product we are reviewing, the name might look long and complicated, but it actually tells us something important: this recoil pull starter is designed to fit a wide range of small 2‑stroke gas generators, including Harbor Freight Tail Gator and Storm CAT units, ETQ, Pulsar, PowerPro, and several others.

Generator Models This Recoil Pull Starter Fits

Before we buy any replacement part, we want to know one thing clearly: will it fit our generator? This product is marketed as a compatible replacement for many popular small portable gas generators, mostly in the 63–72cc range and roughly 800–1200 watts.

Key Compatible Brands and Models

We might recognize some of these brand names from our own garages or workshops. These are common budget and mid-range generators that many of us use for camping, tailgating, light jobsite work, or emergency backup.

Here are the main generator lines this recoil starter is designed for:

- Harbor Freight Tail Gator 63025, 63024 (800–900W, 2-stroke)

- Harbor Freight Storm CAT 60338, 66619, 69381 (800–900W, 2-stroke)

- ETQ950 and TG1200

- Pulsar PG1202S

- ET650 and ET950 gas motors

- A-iPower AP1000 (63cc portable gas generator)

- All Power America APG3004, APG3004A, APG3004D

- Bluemax, Tool Shed, Sigma GEN1250, GEN1250A

- Buffalo Tools Sportsman GEN1000 (800–1000W)

- Coleman Powermate CM04101 (69cc, 900–1000W)

- DuroPower DP800, DP1000 (2HP, 800–1000W)

- DuroStar DS1050 (2HP, 1050W)

- Energin 51769 1250XL (1250/800W, 63cc)

- Jiangdong Contractor Line (2HP, 800–1250W)

- Kenowa Truelife (63cc, 2HP, 850–1280W)

- Kipor 2HP 2‑Stroke (700–1000W)

- Mach Force 1E45F 2‑stroke 2HP 1800W

- Power Smart PS50 (1000W)

- PowerPacPlus Robot 850 HT1200C, HT1200L (63cc)

- PowerPro Technology 56100, 56101 (900–1000W)

- Speedway Yamada 2HP 2‑stroke 1000W

- Titan Industrial TG1000 (850–1000W)

- WEN 56105, 56101 (1000W portable gas generators)

Quick Compatibility Reference Table

To make it easier for us to quickly check our model against this replacement recoil starter, here is a simple reference table:

| Brand / Line | Model(s) | Engine Size | Wattage Range | Fuel Type |

|---|---|---|---|---|

| Harbor Freight Tail Gator | 63025, 63024 | ~63cc | 800–900W | 2‑stroke gas |

| Harbor Freight Storm CAT | 60338, 66619, 69381 | ~63cc | 800–900W | 2‑stroke gas |

| A‑iPower | AP1000 | 63cc | ~1000W | 2‑stroke gas |

| ETQ | ETQ950, TG1200 | 63cc | 1000–1200W | 2‑stroke gas |

| Pulsar | PG1202S | 72cc | 900–1200W | 2‑stroke gas |

| Buffalo Tools Sportsman | GEN1000 | – | 800–1000W | 2‑stroke gas |

| Coleman Powermate | CM04101 | 69cc | 900–1000W | 2‑stroke gas |

| DuroPower | DP800, DP1000 | 63cc, 2HP | 800–1000W | 2‑stroke gas |

| DuroStar | DS1050 | 2HP | 1050W | 2‑stroke gas |

| All Power America | APG3004, APG3004A, APG3004D | – | ~1000W class | 2‑stroke gas |

| WEN | 56105, 56101 | – | 1000W | 2‑stroke gas |

| PowerPro Technology | 56100, 56101 | – | 900–1000W | 2‑stroke gas |

| Titan Industrial | TG1000 | – | 850–1000W | 2‑stroke gas |

| ET650 / ET950 | Various | – | ~650–950W | 2‑stroke gas |

If our unit appears on that list or uses a very similar 63–72cc 2‑stroke engine in the 800–1200W range, this starter is likely to be a direct or near-direct fit.

Why We Might Need a Replacement Recoil Pull Starter

We usually do not think much about our recoil starter until something goes wrong. However, this part takes a lot of abuse over the life of a generator.

Common Reasons the Original Starter Fails

We might have run into one or more of these issues:

- The pull cord snapped after years of yanking

- The spring no longer retracts the rope properly

- The internal pawls fail to engage the flywheel

- The plastic or metal housing cracks or warps

- Corrosion or dirt has jammed up the mechanism

When that happens, the engine might still be perfectly fine, but without a working recoil starter, the generator is effectively dead. That makes replacing the pull starter one of the most cost-effective ways to bring our unit back to life.

Why Replacing the Entire Assembly Can Be Easier

We can repair some starters by replacing only the cord or the spring, but that can be fiddly and time‑consuming. With this product, we are getting a complete recoil starter assembly. That means:

- Pre‑wound spring

- Handle and rope already installed

- Housing and internal engagement parts ready to go

For many of us, swapping the entire assembly saves time and frustration compared to rewinding springs or threading new rope into an old unit.

Build Quality and Design Features

We want to know whether this replacement part feels flimsy or whether it can stand up to regular use. While we do not have the part in our hands in this explanation, we can look at the general design and what users usually expect from this type of aftermarket recoil starter.

Housing and Material

Most recoil starters for small generators like these use a combination of metal and durable plastic:

- Metal center cup or engagement plate to connect with the engine

- Sturdy plastic or metal outer housing

- Internal metal spring and pawls

This replacement starter is designed to match or closely resemble the original OEM style used on Tail Gator, Storm CAT, and similar generators. That means:

- Compatible bolt pattern

- Proper crankshaft engagement depth

- Rope exit angle that feels natural when we pull

Rope and Handle

The rope and handle are critical to comfort and durability. With small 2‑stroke engines, we might give the starter several pulls in cold weather, so we want:

- A comfortable, easy‑to‑grip handle

- Rope of sufficient thickness to avoid early fraying

- Smooth retraction to avoid cord tangling

Because this starter is made to work with units up to around 1200W and engines up to about 72cc, the internal spring tension and rope length should be tuned for that engine size. That balance matters for both longevity and ease of starting.

Installation Experience: How Hard Is It to Replace?

When we think about installing this recoil pull starter, we usually care about two things: tools required and total time.

Tools We Are Likely to Need

While specific generators vary slightly, we will usually need:

- A basic socket set or wrench set (often 8mm, 10mm, or similar)

- A Phillips or flathead screwdriver for some models

- Possibly a hex key set, depending on the unit

In most cases, we are simply removing a handful of bolts that hold the old recoil in place and then swapping in the new one.

Typical Step‑by‑Step Overview

The exact steps can vary by generator model, but the general process tends to look like this:

-

We make sure the generator is off, cool, and with the spark plug wire disconnected for safety.

-

We remove any outer shrouds or covers that block access to the starter housing.

-

We unbolt the existing recoil starter assembly from the engine.

-

We compare the new recoil starter with the old one to check bolt pattern, depth, and engagement cup.

-

We mount the new starter onto the engine with the existing bolts.

-

We slowly pull the handle a few times to make sure the starter engages the flywheel cleanly and retracts properly.

-

We reinstall any removed shrouds or protective covers.

For many of the generators listed, the swap can often be done within 15–30 minutes, even for those of us with only basic mechanical skills.

Performance: How It Feels to Use

We often judge a recoil starter by how it feels under our hand each time we pull. With a proper fit and functional assembly, the performance should be predictable and smooth.

Pull Smoothness and Resistance

On a healthy 2‑stroke engine in the 63–72cc range, the pull should feel:

- Light to moderate in resistance

- Even across the entire stroke

- Without grinding, skipping, or jerking

This replacement starter aims to restore that original feel. If our old unit had a sticky return or a harsh “catch” point, we will likely notice an immediate difference once the new assembly is installed.

Engagement and Reliability

We need the internal pawls or engagement dogs to reliably connect with the flywheel every time we pull. A failing starter often:

- Spins freely without cranking the engine

- Engages erratically

- Slips and causes us to waste effort

Since this recoil starter is made for a variety of known generator models, the engagement system is designed to match the flywheel pattern on these engines. That should translate to consistent engagement as long as the installation is correct and the engine itself is in good condition.

Compatibility Details for Specific Popular Models

Because this recoil pull starter tries to cover many generators, we might want reassurance for a few of the most common ones we see in real‑world use.

For Harbor Freight Tail Gator and Storm CAT

The Tail Gator and Storm CAT lines from Harbor Freight are widely used as budget small generators. The specific models listed for compatibility include:

- Tail Gator 63025, 63024 (800–900W)

- Storm CAT 60338, 66619, 69381 (800–900W)

These units share similar small 2‑stroke engines, and the recoil starter is one of the most common failure items. In most cases, this replacement will bolt on without modification, because it is directly advertised for these model numbers.

For ETQ950 and TG1200 Generators

The ETQ950 and TG1200 are also common among compact portable generators. Here we usually get:

- Around 63cc engine displacement

- Output in the 1000–1200W range

The recoil starter for these generators often shares a similar pattern to the Tail Gator style. This product specifies compatibility with both ETQ950 and TG1200, which suggests a correct mounting pattern and engagement depth for those engines.

For Pulsar PG1202S and Similar Units

The Pulsar PG1202S uses a slightly larger 72cc 2‑stroke engine with up to 1200W output. Even with the larger displacement, the recoil starter design is very similar.

This starter is listed for PG1202S, which tells us:

- The mounting bosses line up

- The rope routing and exit direction work with the shroud design

- The engagement system matches the flywheel

We should still verify our exact model number on the generator’s data plate, but if we have a PG1202S, this replacement should be in the correct family.

Pros of This Recoil Pull Starter

When we consider whether this is a good product for us, it helps to spell out the advantages clearly.

Broad Cross‑Compatibility

The biggest strength here is how many units this starter claims to support. Instead of being locked into a single OEM brand or chasing obscure part numbers, we get:

- Compatibility across Harbor Freight, ETQ, Pulsar, PowerPro, Titan, WEN, and more

- Support for many 63cc to 72cc 2‑stroke engines in the 800–1200W class

- The ability to revive older or discontinued generators

Cost‑Effective Repair

Replacing the recoil starter instead of replacing the entire generator can save us a lot of money. On small budget units, many of us assume the whole generator is disposable, but:

- A new starter costs far less than a new generator

- The engine, alternator, and frame often have plenty of life left

- We reduce waste by repairing instead of discarding

Simplicity of the Complete Assembly

Getting the entire recoil assembly ready to mount means we avoid:

- Wrestling with springs under tension

- Measuring and tying our own starter rope

- Rebuilding worn internals on an old housing

For many of us doing this in a garage or driveway, that simplicity can be the difference between a quick fix and a frustrating afternoon.

Potential Drawbacks and Limitations

No replacement part is perfect for everyone. We also need to think about the limitations before we buy.

Not Guaranteed for Every Variant

Even when a generator shares a brand and watt rating, small changes across years or production batches can cause:

- Slight differences in bolt pattern

- Different shroud shapes that interfere with rope exit

- Modified flywheel engagement designs

Because of that, we should:

- Double‑check the exact model number on our data plate

- Compare photos and measurements if the seller provides them

- Be prepared for minor adjustment or, in rare cases, an imperfect fit

Mostly Aimed at 2‑Stroke, Small Gas Generators

This product is very much tailored to:

- 2‑stroke engines

- Displacement roughly from 63cc to 72cc

- Output typically 800–1200 watts

If we have a larger 4‑stroke generator, an inverter generator, or a different engine family, this is not the right starter for us. Using it outside its intended range will likely result in fitment problems or premature wear.

How This Replacement Starter Affects Our Generator’s Lifespan

When we put a new recoil starter on an older generator, we might be wondering if we are just buying a little more time or if it meaningfully extends the unit’s life.

Restoring Starting Reliability

A healthy starter makes it much more likely that we will actually use and maintain the generator, which in turn supports its long‑term health. If we struggle to get the unit started, we might:

- Avoid using it unless absolutely necessary

- Neglect regular exercise runs that keep seals and carburetors healthy

- Put off maintenance until problems stack up

With a reliable starting mechanism, we are more inclined to:

- Run the generator monthly or quarterly

- Keep fuel fresh

- Notice and address small issues earlier

Balancing Cost vs. Remaining Life of the Generator

If the rest of the generator is in good shape—decent compression, stable voltage output, no major oil or fuel leaks—then a new recoil starter can add years of usable life.

However, if our unit already has:

- Very low compression

- Severe corrosion

- Repeated carburetor and ignition issues

Then it might be time to consider whether investing in this part is the best use of our money. In many cases though, especially for mid‑life units, this kind of repair is a smart way to stretch our investment.

Practical Usage Scenarios

It can help to picture when and where this recoil starter makes a difference in our real lives. That context can tell us how important a reliable starter is.

Camping and Outdoor Recreation

When we bring a small 800–1200W generator for camping, tailgating, or RV backup, we often depend on it to power:

- Small lights

- Phone chargers and small electronics

- A small fan or compact heater (where safe and permitted)

- A small TV or radio

In those settings, we usually do not have backup power. If the pull starter fails at our campsite, we might be stuck without electricity. Replacing a weak or damaged recoil before a trip can save us a lot of frustration later.

Emergency Home Backup

While small 1000W generators are not whole‑house solutions, they can still be critical during outages for:

- Charging phones and laptops

- Running a small lamp or LED lighting

- Powering a small fan or compact device

If we keep a Tail Gator, Storm CAT, or similar unit as part of our emergency kit, having a reliable recoil starter is key. When the power goes out at night in bad weather, we do not want to discover the rope will not retract or the mechanism will not engage.

Light Jobsite or DIY Use

Some of us use these small generators for:

- Running light power tools

- Supporting outdoor DIY projects

- Providing temporary power where outlets are not available

On a jobsite or in a backyard project, a working starter is the difference between getting work done and packing up early. This replacement part can keep an older generator productive in those roles.

Maintenance Tips to Help Our New Starter Last Longer

Once we install this recoil pull starter, we can take a few simple steps to keep it working smoothly for as long as possible.

Gentle but Firm Pull Technique

How we pull the starter affects its lifespan. We might try to:

- Pull steadily instead of yanking violently

- Allow the rope to retract under spring tension instead of letting the handle snap back

- Avoid pulling beyond the natural rope limit, which reduces stress on the spring

These habits reduce shock on the internal components and help prevent cord breakage.

Keeping Dirt and Moisture Under Control

Dust, mud, and moisture can cause the spring and pawls to corrode or bind up. To help avoid that:

- We store the generator in a relatively dry, sheltered area

- We wipe off mud or debris from around the starter area after use

- We avoid high‑pressure washing directly into the starter housing

For generators used around construction or in very dusty areas, occasional light cleaning around the recoil housing can make a big difference.

Comparing OEM vs. Aftermarket Starters

We might be wondering whether this recoil is exactly OEM or an aftermarket equivalent. Products like this are often aftermarket, which has pros and cons.

Benefits of Aftermarket Replacements

With aftermarket options, we often see:

- Lower cost than OEM parts

- Wider availability, especially for older or discontinued models

- Cross‑compatibility across multiple brands using similar engines

That is helpful for generators like the Tail Gator or older ETQ units where original manufacturer parts might be scarce or expensive.

Potential Tradeoffs

At the same time, aftermarket parts can come with some considerations:

- Slight differences in finish or appearance

- Occasionally minor fitment quirks that require adjustment

- Variable material thickness or spring tension compared to original

For most users, the cost savings and availability outweigh minor cosmetic differences, as long as the fit and function are acceptable.

How to Confirm Fit Before We Order

Since this product supports many generators, we might want to verify fit as much as we can upfront. Here are some practical steps we can take.

Steps We Can Take at Home

We can:

- Check the exact model number on our generator’s data plate or label

- Confirm whether our unit is 2‑stroke and roughly in the 63–72cc, 800–1200W range

- Compare our recoil starter visually with product photos if available

- Count the mounting bolts and note their pattern

If our model name appears in the listed compatibility, we are already off to a good start. If it does not, but the engine size and shape look similar, we still might have a compatible engine, especially for off‑brand units that used the same powerplant as a name‑brand model.

User Experience and Real‑World Value

From our perspective as generator owners, the value of a part like this comes down to whether it gets our machine starting reliably again and how much hassle it saves us.

What We Gain by Replacing a Worn Starter

By installing this recoil pull starter, we typically gain:

- Reliable engagement on each pull

- Smooth rope operation that feels secure

- Renewed confidence in bringing our generator on trips or relying on it in an outage

We no longer have to baby an old starter that only works some of the time, or worry about the rope snapping at the worst possible moment.

The Peace of Mind Factor

A small generator is often a backup plan by nature. We keep it ready for power outages, remote work, or outdoor events. Knowing that the one mechanism we need to start it—the recoil starter—is in good shape gives us:

- Less stress during emergencies

- More willingness to lend or use the generator

- Better overall satisfaction with an older unit

In that sense, the product’s value is not just mechanical; it is also about our confidence in our equipment.

When This Product Is a Great Choice for Us

It helps to clearly spell out the type of owner and situation where this recoil pull starter makes the most sense.

Ideal Situations

This starter is a strong match for us when:

- We own a Harbor Freight Tail Gator 63025/63024 or Storm CAT 60338/66619/69381

- We have an ETQ950, TG1200, Pulsar PG1202S, PowerPro, Titan TG1000, or similar small 2‑stroke generator

- Our existing starter rope is broken, sticking, or not engaging the engine

- The engine still runs well and the generator otherwise performs reliably

- We prefer a complete bolt‑on assembly instead of repairing the old starter

In these cases, the cost vs. benefit of this part is very favorable, and installation should be straightforward.

Situations Where We Might Reconsider

On the other hand, this might not be ideal if:

- Our generator is a larger 4‑stroke model or a very different design

- The engine is already near the end of its life with poor compression or major mechanical issues

- We cannot find our model or an equivalent engine on the compatibility list and we are unwilling to risk a trial fit

In such situations, we might be better off looking for a more specific OEM part or considering a new generator altogether.

Our Overall Take on the Recoil Pull Starter

Looking at the details, we can sum up our view of this product in practical terms.

We are getting a broadly compatible recoil pull starter designed for many popular small 2‑stroke gas generators in the 800–1200W range, including well‑known models like Harbor Freight Tail Gator and Storm CAT, ETQ950, TG1200, Pulsar PG1202S, and various A‑iPower, DuroPower, DuroStar, PowerPro, Titan, and WEN generators. The key benefit is the ability to revive a generator that still has plenty of mechanical life but has been sidelined by a failed starter.

By providing a complete assembly—rope, handle, spring, housing, and engagement components—this product offers a practical, relatively simple repair path for those of us comfortable with basic hand tools. In many cases, installation is a straightforward unbolt‑and‑replace process that can be completed in under an hour.

We do need to verify compatibility with our exact model, especially for lesser‑known or off‑brand units. However, for the named models in the product description, this recoil starter serves as an effective and economical solution that can extend the useful life of our generator and restore confidence in its readiness.

If we rely on a compact 2‑stroke generator and the recoil starter has become our weak link, this replacement can be a very sensible way for us to keep our equipment running, without investing in an entirely new machine.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.